We are in the era of tech advancements in the solar energy sector. In 2025, panels such as Thin-Film PV have become the talk of the town for their flexibility, low weight, and stable efficiency. The use case of a thin film panel spans both residential and industrial purposes, making it one of the three main categories of solar panels available today.

So what is a thin-film panel? How different is it from polycrystalline and monocrystalline alternatives? Let us check out!

Thin Film Panels: An Overview

Thin Film solar panels are made using thin layers of solar PV materials that are combined over a few layers. These thin sheets are then layered over materials such as glass, metal, or a plastic surface as the base. This makes thin-film panels extremely lightweight in comparison to monocrystalline and polycrystalline alternatives. With the ergonomics in contention, these panels are portable and fit perfectly over buildings and congested urban terraces.

What makes thin film stand out is its rigid silicon structure, which makes it suitable for a variety of surfaces and fits in perfectly. Although the efficiency of thin film might not be as contrasting as crystalline panels, the versatility of these setups ensures better efficiency.

Types of Thin Film Solar Cells

There are three distinct types of thin film solar cells that are used for different utility purposes. These are made differently, using a combination of metal alloys, and thus have varying levels of efficiency.

- Amorphous Silicon (a-Si): Amorphous Silicon is the most widely used type of thin film module. Although the efficiency of Amorphous Silicon is under 10%, the usability and robustness make it one of the better choices for usage in thin film panels.

- Cadmium Telluride (CdTe): Cadmium Telluride is the second most popular type of material used in designing thin film panels. Despite having a lower production cost, the panel is often known for generating a larger carbon footprint. In addition, these materials, especially Cadmium, have a higher toxicity factor, which makes CDTE solar cells challenging for usage.

- Copper Indium Gallium Selenide (CIGS): Also known as CIGS, these thin film panels are made by combining Copper, Indium, Gallium, and Selenide to form an efficient interface. These panels are widely used on non-flat surfaces, covering most industrial and even residential terraces. CIGS solar panels are also extremely portable-friendly, which allows for easy transportation.

Advantages and Limitations of Thin Film Solar Panel

Advantages

- Light-weight: Thin film solar modules are lightweight, which makes them easy to carry and install on almost all types of surfaces.

- Inexpensive design: Thin film solar cells are comparatively cheaper to manufacture, design and deploy. The initial cost of installing thin film is therefore more affordable.

- Low-light performance: Thin film solar panels perform exceptionally well in low-light conditions and generate effective output even during cloudy conditions.

- Sustainable Alternative: Thin-film solar panels have the least carbon footprint of any solar panels. These are ideally suited for people who are conscious of eco-friendly policies.

Disadvantages

- Lower Power Output: Unlike the other crystalline panels, thin film has a lower generation efficiency of around 12-15%. This makes it the third choice for people intending to use solar for residential/ commercial purposes.

- Lesser life span: With a lifespan of 10-20 years, this is at least 5-10 years less than what an average crystalline panel could deliver.

Thin Film vs. Crystalline Solar Panels (Comparison Table)

| Feature | Thin Film Panels | Monocrystalline Panels | Polycrystalline Panels |

| Efficiency | 12–15% | 18–22% | 15–18% |

| Lifespan | 10–20 years | 25–30 years | 20–25 years |

| Weight | Very lightweight | Heavy | Heavy |

| Cost | Affordable | High | Moderate |

| Best Use Case | Portable, urban rooftops, BIPV | Limited rooftop space, high-efficiency needs | Budget-friendly residential |

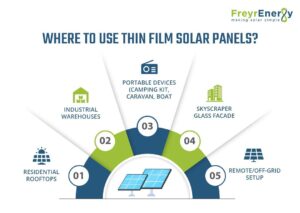

Where to Use Thin Film Solar Panels?

- Residential Rooftops: Especially in urban homes with limited load-bearing capacity.

- Industrial Warehouses: Large rooftops where lightweight installation is key.

- Portable Devices: Camping kits, boats, caravans, and emergency power supplies.

- Building-Integrated PV (BIPV): Skyscrapers, glass facades, and urban designs.

- Remote or Off-Grid Areas: Lightweight setups with easy installation.

Final Thoughts

Thin film solar panels have their own set of reasons for their popularity. The versatility, backed by a simple design, makes it ideal for use across all types of services and is even portable. Visit Freyr Energy today if you are interested in having thin film installed on your property.